Today’s parts haul: 2nd pair of H-sport control arms, bracket for headlight leveler, and replacement lines for BBK, all from the good folks at Detroit Tuned!

Also received a couple of Jegs fender pads, to attempt to protect my new paint once Locutus Mk2 gets back from the paint shop and I start the rebuild.

Friday’s parts haul from my friends at eMINIparts.com!!!!

Left wishbone, pair of tie rods, new hood scoop, assorted hardware, and SWAG!!!

Stephen and his management have gone above and beyond, to help me with the Locutus rebuild project. Supporters of all-things-MINI, eMINIparts.com‘s sponsorship helps make Motoring Alliance possible. Stephen has worked on creative ways to help me save money on parts and shipping, and has earned my business as the “official” OEM parts partner for my rebuild. They deserve your business, too. Give them a shot!

I also received this very handy set of “extra hands” for use under the lift… OTC Underhoist Stand…

I couldn’t find a good quality, budget priced stand sized appropriately for mid-rise lifts. So I’ll cut this one down by about a foot.

That proved to be easier said than done. The bottom of the main tube was both drilled for a through pin (expected) and turned down a bit to fit in the base tube (not expected). Since I don’t have a metal lathe handy to reduce the outside diameter of the pipe, I’m not going to chop off the bottom.

The top had an 3″ sleeve pressed in, to reduce the ID to fit the inner shaft, and with a ledge to hold the bearing race. I managed to drive this sleeve out (using a jack handle, which was the perfect size), chopped off 12″, and re-installed the sleeve.

Done!

Already used it today, to help hold the new wishbone I was installing.

I have the front left suspension back together (nominally), so it’s kinda rollable. The left tie rod is quite bent, so the shell has massive toe-out. But it’s better than it was. This will all be fixed later.

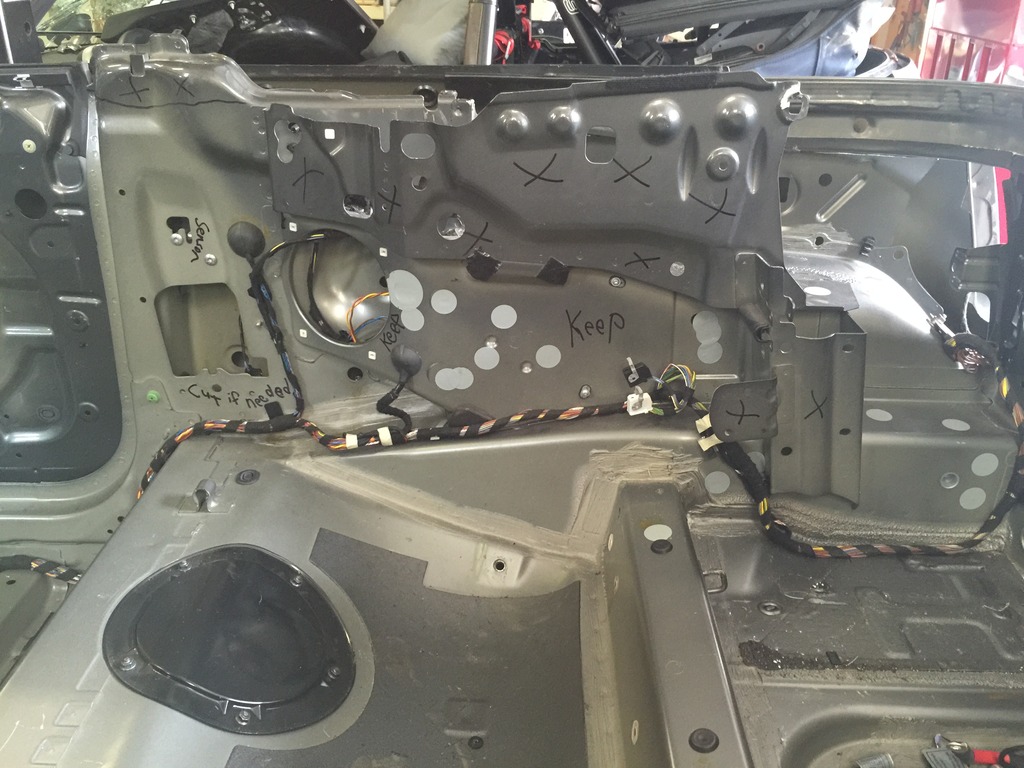

I’m just working to get the car ready to deliver to my cage fabricator tomorrow. Finishing the stripping of the interior, have another hour or so of work to do on that. Then will cut out some extra sheet metal in the rear.

Making progress.