Price agreed upon and deposit placed on R52 shell and some other needed parts. Probably picking it up in SC on 8/22 and dragging it home. So there can be three broken MINIs parked in my garage and driveway.

Decoded the VIN… the shell is just about perfect

11/2005 build, had DSC, Xenons, HK, cold weather package, multi-function wheel, just like my car. So the body / audio harness will be correct for the swap.

Manual, so I’ll now have a manual body harness and the goodness that goes with that.

Fixes an “unfixable” issue with my old car.

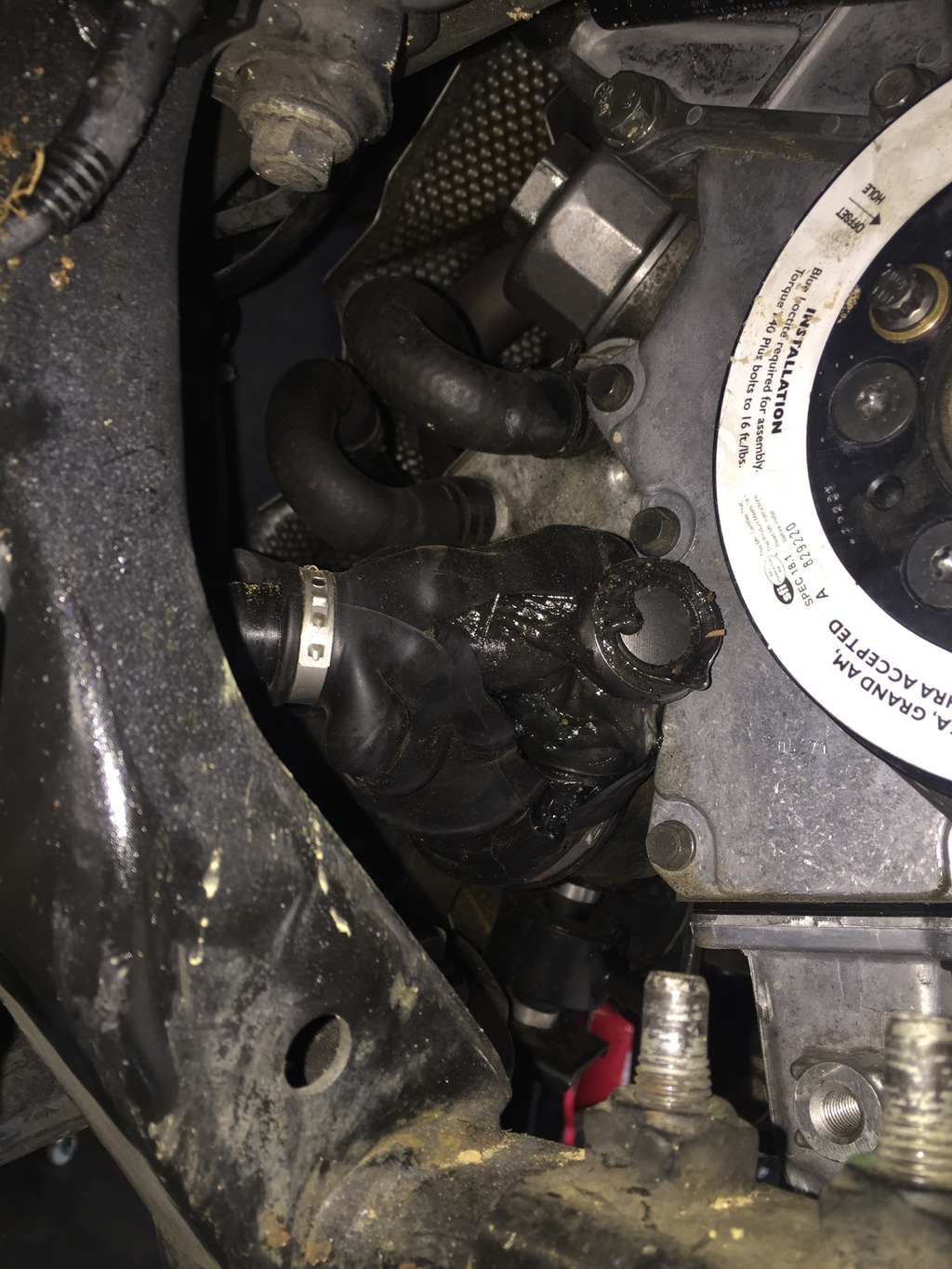

First look at the donor shell – these plus many other pics, plus lots of Q&A with the owner sealed the deal. HUGE shout out to Markus Richard and Doug Lavigne for helping me find this. Social media works.

This was an Ohio salvage vehicle, now in South Carolina. Very little rust for a snow belt car. I’ll remove rust and repaint, use better parts from my wreck, or buy new parts and hardware as needed to make the rebuild as close to “like new” as practical.

The car took a direct hit to the left front wheel, broke the strut, damaged hood, headlight, radiator surround, bumper, fog light, wheel… otherwise, everything looks OK. Strut tower and frame rail look fine. It doesn’t take a lot to total one of these cars… that short list of parts, plus labor and paint, is all it took for this one. The rest of the body looks very clean. Will be mostly stripped when I get it, but will include the taillight and rear left side window that I need. I have most everything else.

I’ll go down on 8/22 with my engine crane and a set of wheels, and help the owner pull the engine and strip anything else he wants to keep. Pop my wheels on it, drag it onto a Uhaul dolly, and drag it home.

First order of business will be to complete stripping the engine bay and trim, for a full Thunder Blue repaint, OEM quality or better, including a new bonnet, GP front bumper, and my GP side skirts. I’ll probably shoot the mirror caps and small GP trim parts myself later.

Already started ordering needed aftermarket suspension stuff last night. This gives me an opportunity to refresh my suspension and take it up a notch. While I loved the Bilstein + Swift + Vorshlag combo, it had become a little too low when on 15″ wheels. Greene Performance coilovers will remedy that. I was still running the original 19mm H-sport swaybar I installed as one of my first mods in probably 2007. Time to upgrade to the H-sport Comp bar. Broke at least one of my several-year-old Powergrid end links, time for a new set of Whitelines from Greene Performance. And some fresh Powerflex Race LCA bushings and steering rack bushing from Detroit Tuned. Already have a set of the new Greene Performance camber/caster plates on order, hopefully they will materialize before I need them.