GREAT weekend at VIR. Ran Full Course on Saturday, and Grand West Course on Sunday. Objective of the weekend was to get comfortable / confident with the new car. Not go super fast, not make great lap times, not engage beast mode… just learn the capabilities and limits of the car.

So I had my crew load up the hauler, and I took a nap on the way to the track.

Claimed our private three-car garage. Actually, that’s true. Because, #ROYALTY

First off, it was COLD. 24F Saturday AM. In a car with no roof, and with the windows down. Seat heaters worked. As did LAYERZ.

Luck of the draw, I got a very good and very laid back instructor. His first time ever on track in a topless car, with arm restraints, etc. He took it well, considering. He also knew pretty much nothing about front wheel drive cars. M3 guy. So I did some schoolin’ over the course of the weekend.

Started out with the Star Specs and took it easy the first session, until things warmed up a bit. Second session, put on the NT01’s and started to build a little speed…

Yeah. The car is a BEAST on track. Lives up to my wildest dreams. It’s very, very quick, and handles very, very well. Thanks to all the (paid for) RMW and Greene Performance and Howerton bits, it just goes without drama.

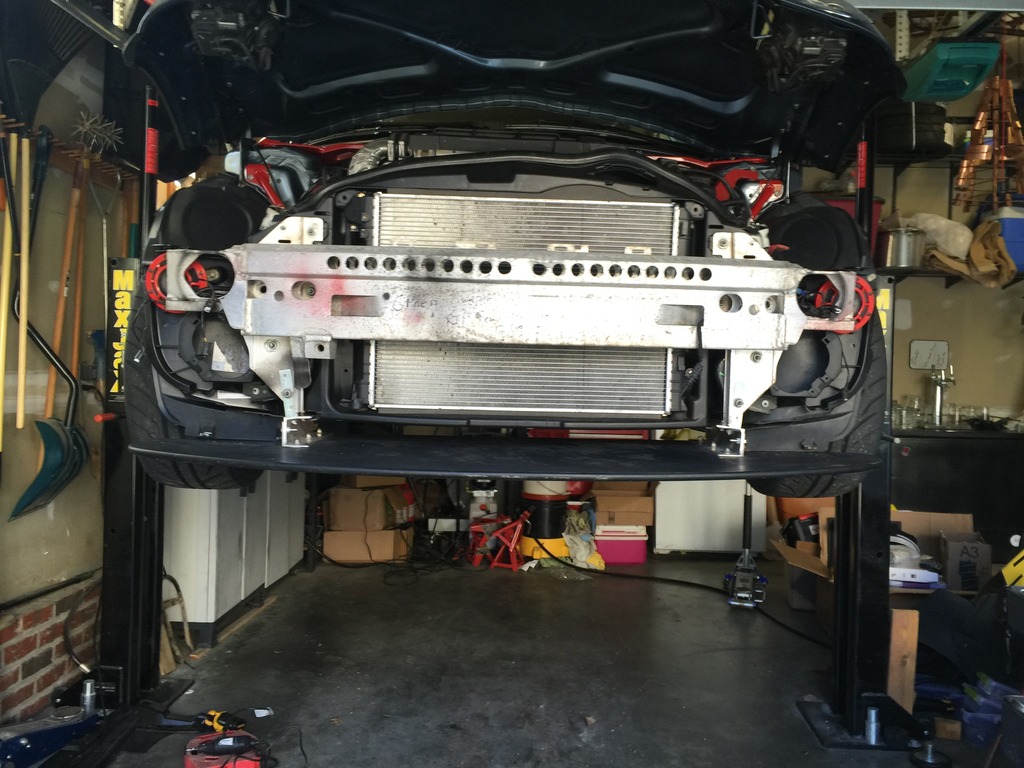

The pic above is at the crest of a hill on the back straight, where my old car (and most MINIs) feel like they’re going airborne at triple digit speed. The new car just sticks to the pavement, thanks mostly to the RMW splitter, plus the other GP aero bits (underbody panels and skirts).

Got many point-bys from all kinds of cars and drivers.

I did give my share of point-bys… like to this very quick Stingray, that disappeared down the back straight at a buck fifty.

Driver still has much work to do, the car has much more speed in it. I personally petered out at about 90 on the Climbing Esses, but I know the car can do over 100 up them, no problem. I just need to build the nerve and smoothness to do it.

The Grand West course on Sunday was a RIOT. This course is practically made for MINIs.

Hard to tell from the map, but the inner loop is VERY technical and twisty, with several rapid elevation changes. Like a roller coaster. I was harassing cars through there all day.

I gotta do that course again, soon.

Late in the day Sunday, the car started getting squirrelly under hard acceleration and braking. On the drive home, I noticed that it got even more pronounced. Like I had something in the suspension moving, altering the alignment dynamically. Sure enough, this morning I found that the left side inner ball joint bolts had backed out enough to let that joint slip fore and aft a bit under load, altering left toe each time it did it. Fixed, and now part of my pre-track checklist to specifically check those bolts. You really don’t want the car steering itself like that when threshold braking at 120mph. Trust me.

Anyway, mission accomplished, and then some. My instructor was giddy when he got out of the car, second session on Sunday. “I learned a lot about what’s possible in a front wheel drive car. I wish I could do some of those sections like that.”

And got some great pics. I have lots of video to review and edit. I’ll post it, eventually.

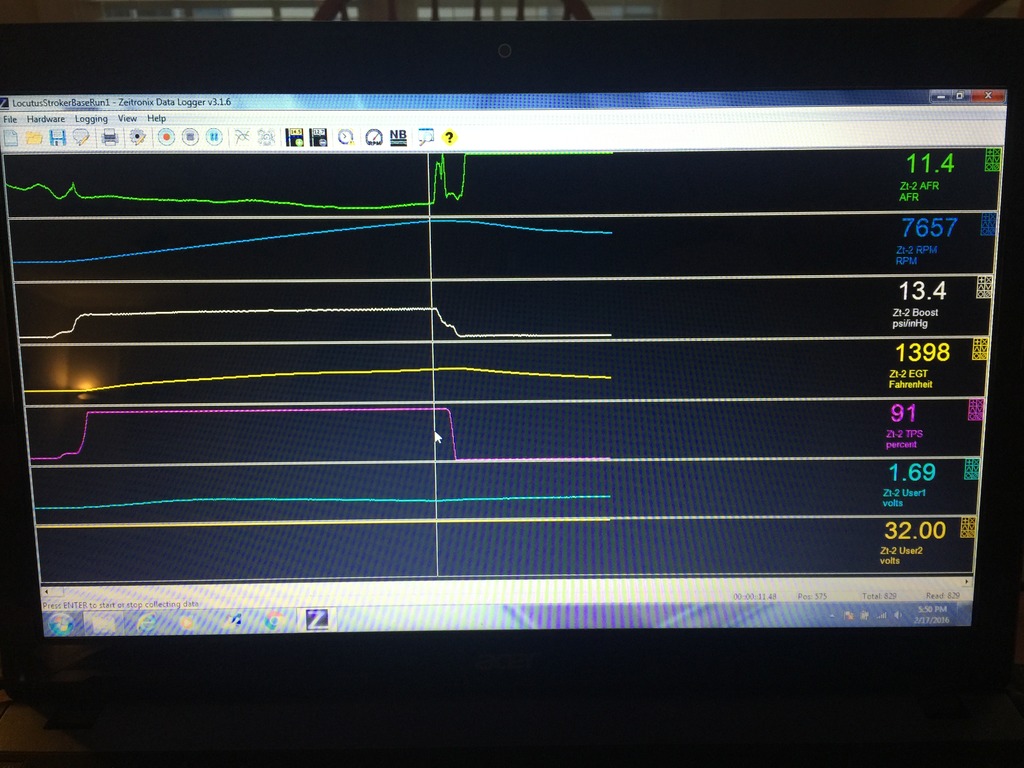

So my LapTimer app lost its mind a bit during the best session of the weekend, and treated the entire session as one long lap. No big deal, I just had to review the video and manually record lap times. I strung together a long sequence of 3:29 to 3:34 laps, getting more consistent. Still lots of room to carry more speed around some of the corners (including the Climbing Esses), run longer in the straights and brake deeper. Many seconds in all that, over time.

Anyway, here’s the extended cut of my entire second session on Sunday, in two parts to keep it Youtube friendly. Please pardon the noise. It is, after all, an iPhone mounted to a steel roll cage on a topless car going 100+ mph. Enjoy. I like it.