Long day cranking on details.

Installed the front bumper for real. Which required as much time hunting through boxes for hardware, as actually working on installing it. First time installing a GP bumper, had to figure out how all the trim and stuff worked. But got it done.

Spent a while working on bonnet alignment. Much better, but still need to tweak it a bit.

Tested windows and lights for the first time. Worked! Installed the knobs that hold the window glass to the regulators. Replaced a couple of bad bulbs in the taillights.

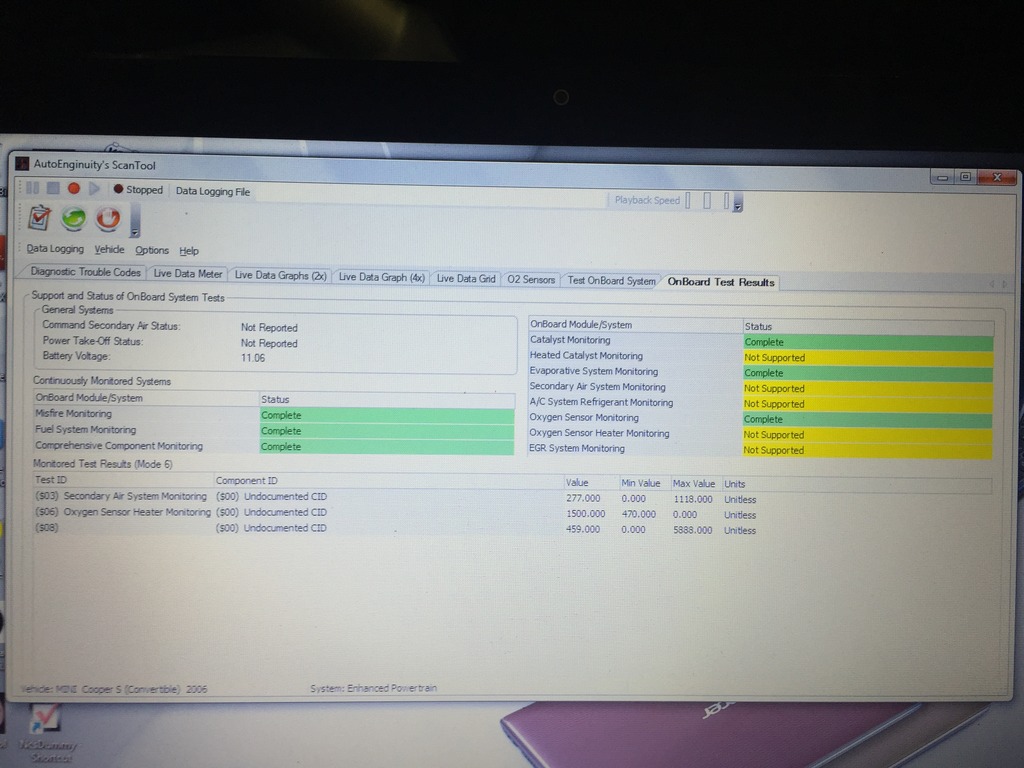

Routed narrowband and wideband O2 and EGT sensor wiring. Have that all buttoned up under the car and in the engine bay. Need to wire the Zeitronix controller in the cabin tomorrow.

Drew up plans for my custom exhaust midpipe. Dropped of exhaust stuff at the good shop across town, showed everything to the dude and explained it. He said “no problem, tomorrow, worst case Wednesday”. That’s what I wanted to hear!

Adjusted ride height on my coilovers. Much better, may need to raise the rear a little more.

Adjusted rear toe, I think I have it much closer. Need to adjust camber front and rear.

Dropped the long exhaust heat shield. Fabricated and installed a little bracket to help maintain clearance under the short shifter, since there’s no bottom on the shifter box. Made it out of a mounting plate I had bought for the kill switch, that I didn’t need.

Modified the battery bracket to fit my lightweight battery. Nice, secure, race-legal metal-to-metal mount. Much better.

Disassembled my spare stereo headunit to experiment with alternate installation locations. I think I have a plan for fitting the whole thing (less the CD player) in the OEM location. That would be cool. Will work on it more tomorrow.

***

Working on street legal odds and ends today. Installed my Longacre rear view mirror (required fabricating some brackets). Got all four corner lights working. Installed one of my Hella Supertone horns. Bolted in my seats. Installed harnesses.

The horn was one of the more challenging things, actually. my steering wheel was missing the horn wiring harness (got removed by me after the crash). After I replaced that, the horn still wouldn’t work when I pressed on the airbag. But It would if I shorted the steering wheel spring plate with a screwdriver. Finally figured out that the spring plate had gotten bent when the airbag deployed. Replaced it with a spare and all was well.

Car is just waiting on the exhaust now. And some legal mumbo jumbo to get the title.

***

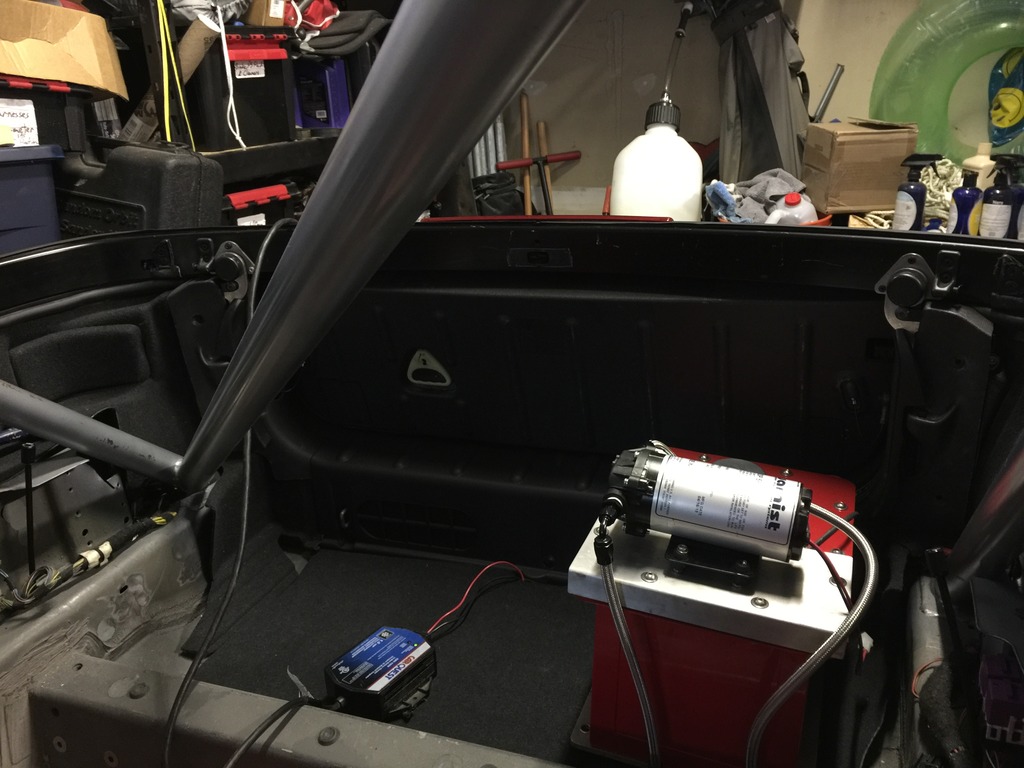

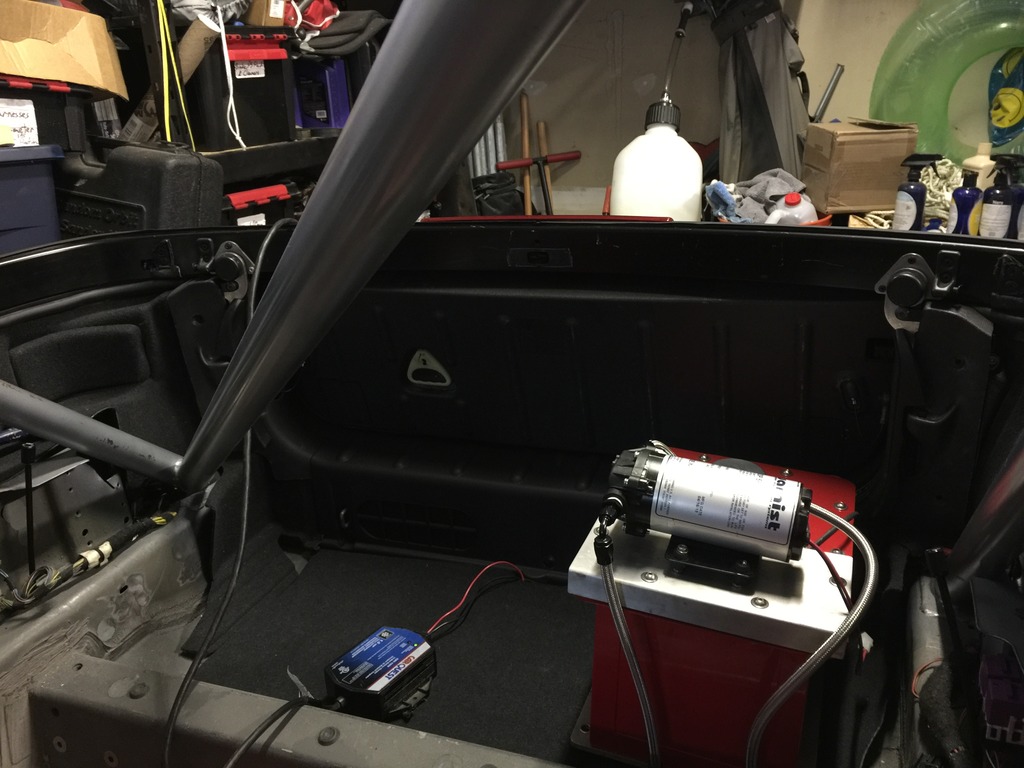

Spent most of the day buttoning up stuff in the cabin, and in the boot.

Wired power to my Zeitronix controller, plugged in the wideband O2 and EGT sensors and the gauge display.

Plugged in my boot hatch, got the plate lights and boot release working, installed trim inside the boot area, cut and drilled new floor panel for the new meth location, cut felt cabrio rear side panels to fit. The rest of the rear will be carpeted, with custom side panels, at a later date. And the whole thing will be covered with the custom tonneau.

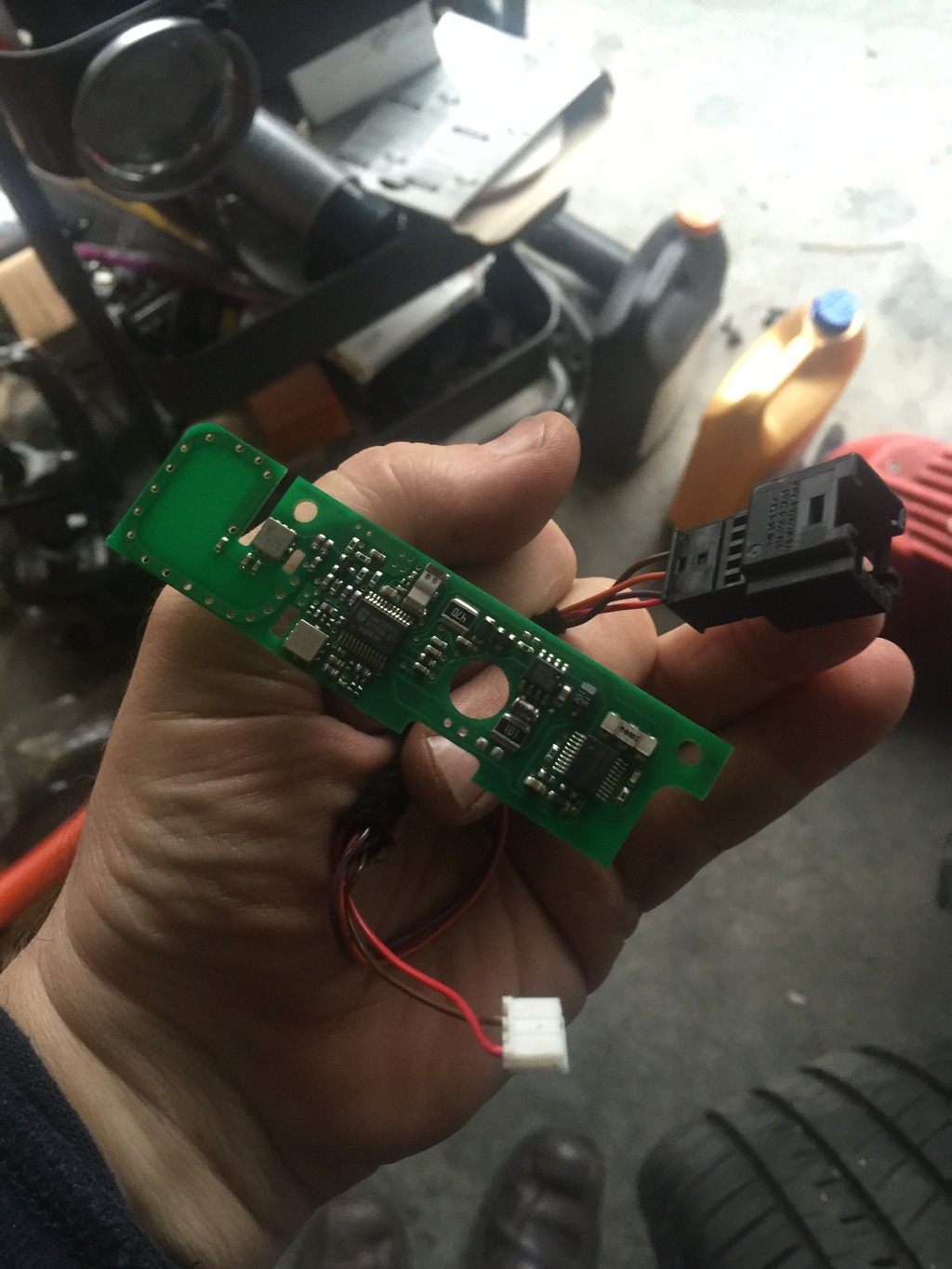

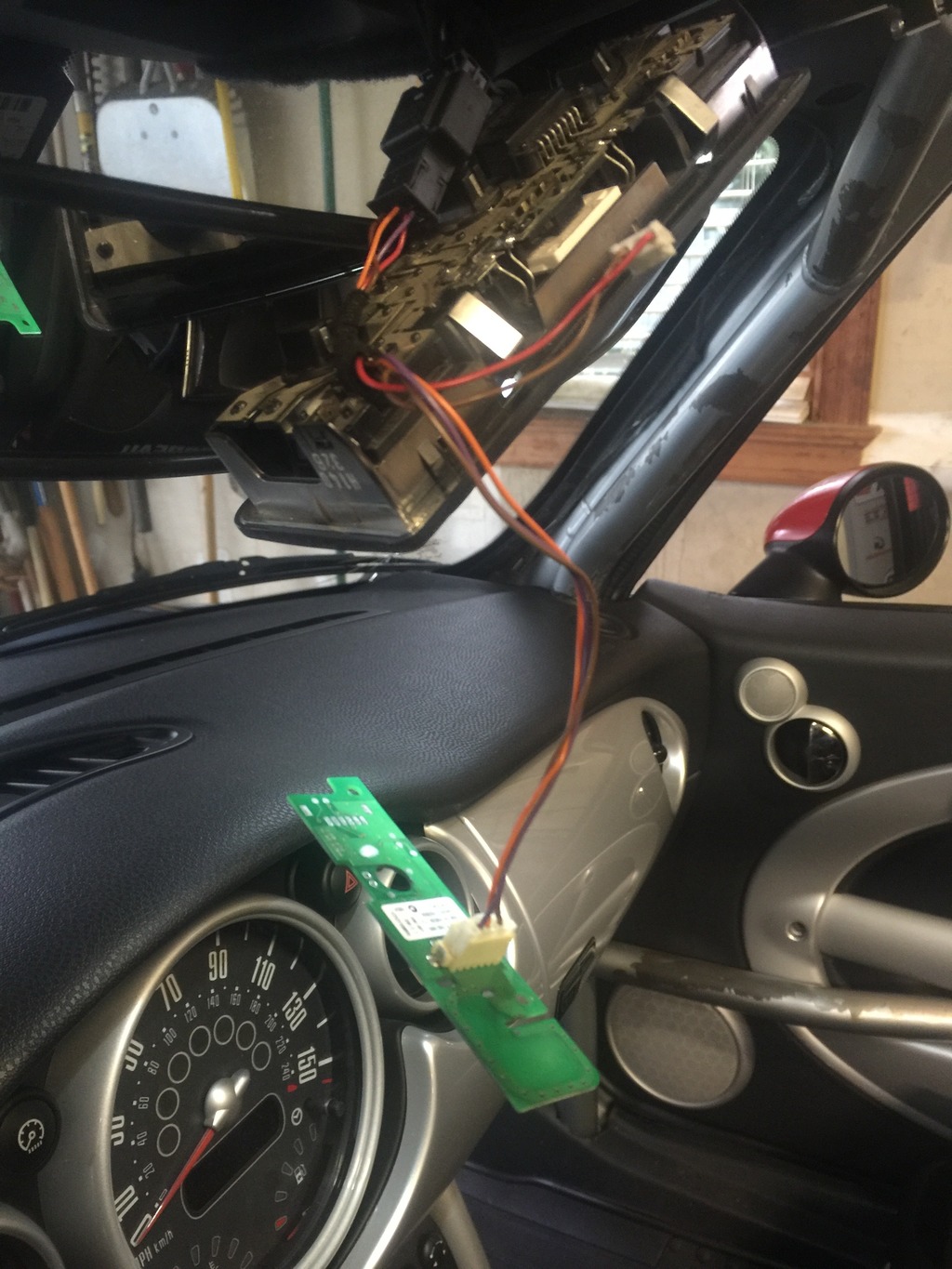

Experimented with the stereo headunit, determined that it would work with the CD player removed, and that the faceplate is easy to reposition, one ribbon cable.

Cut the “ceiling” out of the mounting slot, to free up space to angle stuff upward over the roll cage crossbar.

Chopped the chassis so there would be clearance when it angles upward.

Cabled it up and slid it into place.

Install faceplate, and it looks totally OEM, but isn’t.

Cockpit is pretty much done, except for trimming the bottom edge off the door pads, so they clear the door bars.

Partially unwrapped one of the armrests and trimmed the foam and plastic, then trial fitted it. Looks good. I’ll finish both of them up tomorrow. I’ll shave the exposed bosses on the bottom of the door handle tube, so it’s smooth when you grab it, and will figure out how to affix the pad securely without the lower row of clips.